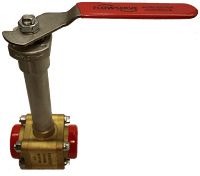

Cryogenic ball valves are high-performance shutoff valves for intermittent and continuous flow applications with temperatures to -425°F. They are used on tough applications involving all types of cryogens, such as oxygen, hydrogen, methane, ammonia, nitrogen, fluorine, LNG and deuterium.

Cryogenic ball valves include unique features to ensure safety and performance in cryogenic applications. Central to the cryogenic design is a rugged, one-piece, pressure safe stem with a Polyfill thrust bearing and stainless steel split ring. It provides design safety and low operational torque. Polyfill seats give you tight shutoff throughout the temperature range. With an orientation-controlled stem/ball connection and an upstream hole in the ball, you get positive overpressure protection.

Summary of specialized design features:

- Positive Ball Cavity Relief – An upstream relief hole in the ball prevents dangerous overpressure due to thermal expansion. On extended stem valves through 2", a one-piece stem with alignment pin assures proper orientation of the ball.

- Pressure Safe Stem – Both one-piece and two-piece, assembled inside-the-body stems are safe from blowout and are supported with Polyfill® thrust washers.

- Zero Leak Packing – Belleville live-loaded TFE packing rings and stem centering followers assure zero leakage through the toughest, high-cycle applications.

- Effective Bonnet Extensions – The stem extensions of cryogenic valves conform to standard industrial practices. That means wall thickness and lengths that keep heat transfer down, the packing frost-free, operational torques low, and actuators solidly supported.

- High-Performance/Low-Thermal Stress – The special “part compatibility” design of valve parts, Polyfill seats and body seals assure tight shutoff, zero body leakage and low torque through large thermal excursions from ambient to -425°F.

Cryogenic valves are normally available in four body configuration, in either stainless steel or brass:

- Three-piece construction - makes it easy to install, versatile in application and simple to maintain.

- The cryogenic diverter valve - accepts media through the bottom inlet port and directs it to one of two side ports.

- The wafer design - a flangeless cryogenic valve that mounts between ANSI Class 150 or 300 flanges.

- A flanged design - has a body cast with ANSI Class 150 flanges.

Application for cryogenic ball valves:

- Over-the-Road LNG-LPG Trailers

- Terminal Unloading Stations

- High-Purity Cryogenic/Gas Systems

- LNG Storage and Distribution

- CO2 and Nitrogen Injection for Enhanced Oil Recovery

- Over-the-Road CO2, LNG, Food Carriers

- Petroleum Refining Unleaded Gasoline (Gas Treatment Skids)

- Lyophilization Systems

- Air Separation Plants

- Liquid and Gaseous Oxygen

- Inerting and Heat Treatment