Valves are critical components of industries that provide the backbone of the modern world. Because valves are standard in engineering, mechanics, and science, each valve must perform to a specific standard. The valve actuator is as crucial to the valve as the valve is to the industry in which it operates.

Actuators are powered devices that move valves between open and closed states; the actuators can be controlled manually or as part of an automated control loop. The actuator responds to a remote control signal. Valve types can be closed, fully open, or somewhere in between, depending on the valve and actuator combination. Current actuation technology enables remote indication of valve position as well as other diagnostic and operational data. Regardless of its power source, whether electric, hydraulic, pneumatic, or another, all actuators create either linear or rotating motion when controlled by a control source.

Multiple valves in a process system are operated in a coordinated manner thanks to actuators; imagine if engineers in a vast industrial environment had to change every valve through a hand wheel or lever physically! While such a manual system may produce jobs, it is, unfortunately, logistically and economically impractical. Actuators make it possible to automate valve action.

Pneumatic actuators use air pressure as a driving force to adjust the position of a valve. Hydraulic actuators are devices that rely on pressurized fluids. Electric actuators, whether motor-driven or solenoid-driven, use electricity to move the valve trim into position. Changes in valve position provide the needed response to maintain the desired process condition. Signals from controllers constantly monitor the process and evaluate inputs, subsequently adjusting the actuator's motion.

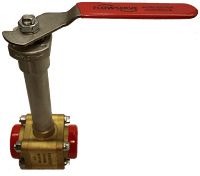

Manual valve operation and regulation are becoming less common as automation gains traction across many industries. Valve actuators serve as the link between control intelligence and physical valve movement. The timeliness and automation advantages of valve actuators also serve as enormous assistance in risk mitigation. Severe tragedies in either environmental conditions or a facility can be pre-empted and rapidly stopped as long as the system is functioning correctly. Manual actuators rely on the hand operation of levers, gears, or wheels in general. Still, valves that are frequently changed (or that exist in remote areas) benefit from an automatic actuator with an external power source for various practical reasons, most notably being located in an impractical area for manual operation or complicated by hazardous conditions.

Actuators serve as industrial keystones to one of the essential control elements of industries worldwide due to their variety and tiered usage. Valves are vital building blocks of industrial processes, just as industries are the backbones of society, with actuators serving as an invaluable device assuring both safe and precise functioning.

Swanson Flo produces tested, certified, and exceptionally reliable actuated valves for fully automated essential valve systems with optimum fit, highest performance, and most extended life. Swanson Flo professionals combine decades of experience and knowledge with a wide range of readily available components that are carefully selected to provide customers with the highest quality and value possible.

Swanson Flo

https://swansonflo.com

800-288-7926