The Swanson Flo Blog is dedicated to provide educational and new product information on process control instrumentation, control valves, and valve automation. For more information on these products, visit SwansonFlo.com or call 800-288-7926.

Swanson Flo: The Low Flow Experts

Actuators and Valve Automation

TYPES OF VALVE ACTUATORS

Demonstration of Ultra Low Flow Control Loop Combining the Equilibar Precision Valve and the Bronkhorst Mini CORI-FLOW™ Meter

Fractional Flow Control Valves from Swanson Flo

For Critical Fractional Flow Control of Liquid, Gas, or Steam

LowFlow control valves have applications in OEM, laboratory, and pilot plant applications. Installations such as these frequently require valve trim changes to meet varying flow requirements for a given application. Monel, Hastelloy, Alloy 20, Titanium, Kynar, and Inconel are just a few of the materials LowFlow offers to address your material compatibility challenges.

Gas Flow Measurement & Control - Aeration Applications

Many processes include gas flow measurement and control. Gas flow meters are standard in laboratories, machinery, industry, hazardous areas, and various markets, including the analytical market, the chemical industry, renewable energy, the semiconductor industry, the food and beverage industry, and surface treatment.

Applications for Aeration

Aeration is when air, oxygen, carbon dioxide, or other gases circulate, mix, or dissolve in a liquid or substance.

Aeration applications are typical in food and beverage markets, wastewater treatment, fish tanks, and fish farms. Controlling oxygen levels in beer brewing and winemaking, for example, allows fermentation. Milk, sparkling water, and other carbonated beverages, such as cola require a throughflow of gases to remove odors or add CO2. Industrial gas flow control, similar to air pumps in a fish aquarium, is used to aerate ponds to grow fish or algae.

Gas Flow Aeration Markets:

- Winemaking and beer brewing

- Production of carbonated beverages

- Fermenters and bioreactors

- Treatment of wastewater

- Farms for fish and algae

Why Bronkhorst?

- Robustness

- High repeatability

- Easy to check actual gas flow

- Gas consumption monitoring

- Ingress protection class IP65 rugged and waterproof housing

Bronkhorst provides mass flow meters and controllers with capacities of up to 5000 ln/min Air equivalent. In aeration applications, up to 50% of MASS-STREAM flow measurement and control instruments include a multi-functional display that provides various additional options.

Bronkhorst is a company that specializes in gas flow measurement and control instruments.

For more information about Bronkhorst products in North Dakota, South Dakota and Minnesota contact Swanson Flo. Call 800-288-7926 or visit https://swansonflo.com.

New Product Alert: The Jordan Valve Mark 75A

Jordan Valve Introduces the Mark 75A Wafer Style Control Valve

Jordan Valve designed the Mark 75A as the next generation of control valves with its modular, stackable actuator. The Mark 75A incorporates a modular, stackable actuator to reduce weight and footprint dimensions further while providing additional torque and all of the benefits of the time-tested Sliding Gate seat design in a lightweight, compact body. The Mark 75A, which is available in 1" through 6" (DN25 - DN150") sizes, is a high-value solution used in a variety of applications.

DOWNLOAD THE MARK 75A DATA SHEET HERE

Mark 75A Advantage: An Actuator with Modularity and Stackability

The new actuator design has an effective diaphragm area of 25 square inches per module and can be stacked to increase the total effective area to 50 or 75 square inches. The use of aluminum in the construction ensures a lightweight automated package.

Mark 75A Advantage: Less Weight

The Mark 75A has a significant weight advantage over other valve designs. A 4" Mark 75A with a 75M actuator weighs 27 lbs. Because of the lightweight and reduced envelope dimensions, transportation, installation, and support costs are lower.

For more information about the Mark 75A in Wisconsin, Indiana, Minnesota, South Dakota and North Dakota, contact Swanson Flo. Call them at 800-288-7926 or visit https://swansonflo.com.

Equilibar® Flow Control Valves Provide Advantages in Precision Flow Control

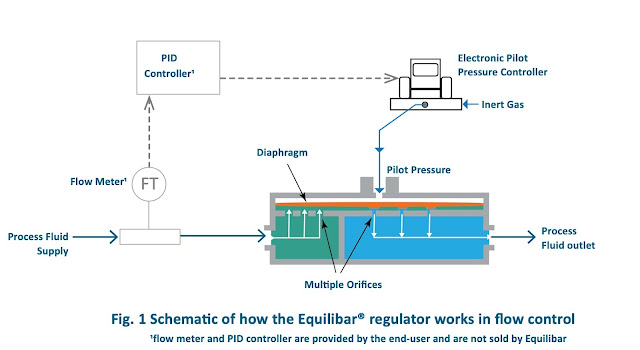

Equilibar® control valves provide precise flow control for gases, liquids, and mixed-phase fluids over a wide range of flow rates. The unique dome loaded multiple orifice design responds quickly to changes in upstream and downstream process disruptions to maintain setpoint,

The Equilibar® control valve works in a completely different way than traditional regulators and valves. Instead of a single valve seat, the Equilibar® valve uses multiple orifices sealed by a flexible diaphragm. The Equilibar® valve is dome-loaded by pressure on top of the diaphragm. The dome loading controls the process fluid flow proportional to that "pilot pressure" on the diaphragm. As flow requirements change, the diaphragm moves a few millimeters to open and close over some or all of the orifices, providing instantaneous and frictionless control. The Equilibar® valve was conceived as a precision back pressure regulator but easily reconfigured to control the flow rate in a flow control PID loop with an electronic pilot controller. Over the years, Equilibar®customers have discovered the significant benefits of the Equilibar®control valve in demanding flow control applications where the supply pressure is mainly stable.

Equilibar® valves can be an excellent solution for closed-loop flow control in complex applications that traditional flow control methods cannot solve. Equilibar® valves improve performance in a variety of demanding applications, including:

- Flow coefficient (Cv) ranges wider than conventional valves (>100:1)

- Extremely low DP and extremely high DP

- Two-phase, phase-change, and supercritical states

- Continuous flow chemistry

- Sanitary applications

The Equilibar® Flow Control Valve's Operation

Equilibar® valves are dome-loaded and pilot operated, which means that gas is supplied to the dome (top) of the valve via a pilot controller to set the process setpoint. In the dome, a direct sealing diaphragm covers a field of orifices and adjusts its position allowing flow through the orifices while maintaining the desired setpoint.

The Equilibar®flow control valve links to an electronic pilot pressure controller and a flow meter in a control loop. (See Fig.1.) To control flow, a proportional-integral-derivative (PID) controller monitors input from a flow transmitter (FT) and adjusts the pilot pressure. The electronic signal from the PID converts into a pressure signal for the pilot controller by an electro-pneumatic transducer (E/P). Increasing the pilot pressure reduces flow, and decreasing the pilot pressure increases flow. The system performs best when the supply pressure is stable.

The Benefits of Using an Equilibar® Back Pressure Regulator for Flow Control

Operates over a Wide Flow Coefficient Range (Cv)

The limited flow range (or max/min ratio of effective Cv) of traditional flow control valves is one of their characteristics. Most control valves used in the research and process industries have a 10:1 to 15:1 ratio. An Equilibar®back pressure regulator is easily capable of operating in a Cv range greater than 100:1.

Multi-Phase Fluid Control

The Equilibar® back pressure regulator's unique design allows it to handle two-phase or mixed-phase flow streams while maintaining high precision. Gas/liquid processes, water/oil flow streams, and supercritical fluids are all examples of this.

Traditional back pressure regulators employ a single annular valve seat, which is frequently very small, so that when slugs of liquid flood the valve throat, the volumetric flow rate drops abruptly as the denser fluid accelerates through the orifice. This brief decrease in volumetric flow disrupts the upstream process pressure's stability.

The Equilibar® technology employs a direct sealing diaphragm over multiple orifices to control pressure drop. The flexible diaphragm can instantly change its proximity to the orifices to adjust to the varying valve coefficient (Cv) requirements of the various phases.

Isolates from Changes in Downstream Pressure

An Equilibar® fluid control valve acts as a pressure buffer in a change in downstream pressure. Equilibar® valves will automatically adjust to maintain the setpoint inlet pressure regardless of process changes at the outlet port. Any change in downstream pressure necessitates a PID control adjustment to maintain stability when using a traditional flow control valve (FCV).

High Resolution

Equilibar® dome-loaded valves have incredibly high resolution, no hysteresis, and no dead band. Minor adjustments to the differential pressure result in high-resolution process control.

Service Conditions That Are Demanding

Because Equilibar® back-pressure regulators have only one moving part, they easily configure for the following severe and demanding service conditions:

- Excessive temperatures

- Extremely corrosive acids

- Sanitary processes

- Ultrapure specifications

Continuous Flow Reactions

In continuous flow chemistry, controlling pressure is critical for phase control, residence time, reaction speed, and equilibrium management. For example, the reaction temperature is an essential factor in reaction efficiency; however, at high enough temperatures, a reagent can reach boiling point, which harms the reaction. Controlling reaction pressure by connecting a back pressure regulator to the reactor's outlet can help prevent reagent boiling.

For more information about Equilibar®, contact Swanson Flo. Call 800-288-7926 or visit https://swansonflo.com.

The Aschroft GXLdp Differential Indicating Pressure Transmitter

The Ashcroft® GXLdp differential pressure transmitter with a display intended for use in pharmaceutical and critical care applications such as isolation and clean rooms, HVAC building automation and comfort control, and sensitive airflow measurements.

The GXLdp allows the user to select between multiple outputs (4-20ma and voltage) and perform field calibration via external pushbuttons. It uses the patented Ashcroft SpoolCal® actuator to provide in-place system calibration without disrupting process connections. It employs Ashcroft's SiGlasTM technology, which offers unrivaled measurement sensitivity and long-term repeatability.

The GXLdp includes features such as PNP or NPN switches that to reduce installation time and costs. It is built to Ashcroft's simple TruAccuracyTM terminal point standard, eliminating confusion from statistically derived accuracy specifications and the need for user calibration during installation.

The GXLdp, which is available in ranges as low as 0.10 in. H2O (25 Pa) is the ideal low-pressure DP sensor for Pharmaceutical and BioTech applications, isolation laboratories, semiconductors, and other mission-critical industries. A three-year product warranty covers it.

Swanson Flo

https://swansonflo.com

800-288-7926

Schneider Electric Process Instruments from Swanson Flo

A single innovative instrument can improve process control and the performance of any of your production assets, including personnel, equipment, energy use, and inventory. Using multiple systems can enhance the performance of all aspects of your business.

Schneider Electric's process instrumentation is combined with various industry-leading brands to produce systems, software, and services that significantly improve your operation's economic, safety, and environmental performance. Furthermore, deploying multiple advanced measurement systems will enhance the availability and utilization of all assets on which your success is dependent.

Foxboro / Schneider Electric Process Instrumentation has been at the forefront of developing numerous breakthrough measurement technologies for decades, including the first D/P cell, the dual-phase Digital Coriolis Mass Flowmeter, the PH10 and PH12 Smart pH sensors and the Magnetic Flowmeter.

Schneider Electric / Foxboro is the industry leader in performance across a wide range of measurement technologies:

- Pressure transmitters with the best-in-class accuracy and the industry's most extended warranties.

- Flowmeter technologies include: Magnetic, vortex shedding, and Coriolis provide an unrivaled solution for liquids, gases, and steam.

- Process analytical sensors are revolutionizing pH and conductivity measurement.

- Temperature transmitters that provide accurate and dependable measurements even in the most extreme conditions

- Level measurement devices, including buoyancy and radar, are available for various installation and application options.

- Wireless Instruments offers long-range wireless, WirelessHart Mesh network over the cloud dataloggers that are self-contained or battery-powered.

Process Instrumentation provides accurate, dependable measurement and analysis of pressure, flow, level, temperature, positioner, and process analytical variables for maximum integration and interoperability — all at competitive prices, low cost of ownership, and 24-hour worldwide support from a single source.

Swanson Flo

https://swansonflo.com

800-288-7926

The Steriflow FBCPM Series Constant Pressure Modulating Valves (CPM)

The Steriflow FB5CPM inlet valve is an air-loaded sanitary constant pressure modulating valve designed to allow users to change setpoints remotely via a cabinet or panel-mounted air regulator.

The JR Series regulator is used to adjust the setpoint range. Alternatively, an I/P transducer or a direct air load can adjust the setpoint range.

In this video, the JR Series regulator is used to adjust the valve set point. The valve is normally closed, and when inlet pressure increases above the valve set point, the diaphragm senses the change in pressure, pulling the plug away from the seat to maintain constant inlet pressure. In contrast, a decrease in the inlet pressure below the air set point causes the air load to force the diaphragm and plug towards the seat into the closed position.

The FB5CPM is a 3A certified inlet valve ideal for sanitary process applications, including HTST/UHT pasteurization fully automating SIP/CIP systems and many other applications where constant pressure maintenance is required.

For more information in Minnesota, Wisconsin, Iowa Indiana, South Dakota, and North Dakota contact Swanson Flo. Call 800-288-7926 or visit https://swansonflo.com.

The Proper Method of Setting Position Limits on the Limitorque L120 Electric Actuator in a Safe Manner

This instructional video shows you how to set position limits on the Limitorque L120 electric actuator safely. Explore the video to learn proper equipment terminology, comprehend the wiring diagram concerning the limit switch contact status, and learn how to read the limit switch position.

Flowserve Limitorque L120 electric actuators solve many flow control problems in various power, oil and gas, and water industry applications.

L120 actuators are proven performers in demanding applications due to their ruggedness, dependability, and versatility. Thousands of L120 actuators are in use in some of the world's most challenging environments, where anything less than everyday dependability is not acceptable.

Refineries, pipelines, terminals, tank farms, cokers, and offshore platforms rely on the L120's safety, endurance, and operational efficiencies. The L120 is network-compatible, has explosion-proof certification, and is lightning and EMI resistant.

The L120's availability, control versatility, and dependable performance are of particular value in power generation plants. The L120's rugged design and construction quality withstand vibration, high-pressure steam, and extreme temperatures.

The L120's low-maintenance requirements and modulating control capabilities benefit water and waste treatment facilities. L120 actuators comply with AWWA standards and integrate simply into the industry's trend toward modern control networks. The L120 Series' diverse range of options enables easy, cost-effective adherence specification requirements.

For more information about Limitorque actuators, contact Swanson Flo. Call them at 800-288-7926 or visit their web site at https://swansonflo.com.

StoneL Valve Communications for Food and Beverage

Reliable Solutions for Networking and Control System Integration

Meeting increasing demand while maintaining safety is a critical factor in the food and beverage industry. This pressure is driving technologies that help meet regulatory requirements while delivering a competitive edge in efficient and economic performance. Proven technologies and enhanced capabilities are helping overcome new challenges.

Food and beverage companies are facing increasing competition and need increased efficiency, reduced costs, and agility. StoneL is working with many global industry leaders to address these needs and requirements with StoneL valve controllers and monitors. A comprehensive service offering and service network support all StoneL products.

Monitoring Precision

The Axiom and Prism platforms use continuous solid-state sensors that have increased reliability and precise position measurement compared to mechanical or proximity-reed technology. These sensors enable more sophisticated valve diagnostics, leading to reduced life cycle maintenance costs.

Compact Size

The Axiom, Prism, and Eclipse products are all rich with features designed to meet the industry’s increasing need for smaller, lighter, and more durable products to conform to modular process skids and flexible manufacturing requirements. For example, the integral solenoid of the Axiom allows for a smaller overall envelope size on the skid, thanks to less connected tubing and cabling needed to complete the valve assembly.

Predictive Maintenance

You can avoid downtime due to valve failure by having easy access to information about critical parameters. Using WirelessLink, you can remotely monitor valve function, including travel position, time to open/close, and cycle count of your valve. This data can help maintenance quickly identify and address a problem before it causes danger or downtime, at the same time allowing you to extend the life of critical valves.

Improving Safety with Wireless Link

The Wireless Link can help you access difficult-to-reach communication and control modules safely and conveniently. Using StoneL secure app on your iOS mobile device may help you achieve further cost savings while keeping you at a safe distance, up to 50 meters away. With access to cycle count data, you can perform valve maintenance when needed and replace parts before wearing out. You can finally forget scheduling maintenance based on calendar days instead of service needs.

Valve automation and networked valve control devices improve the quality and availability of diagnostics data. At the same time, they help reduce maintenance costs and safety risks at your plant.

StoneL FieldLink products and services enable automated valves and instruments to interconnect with your plant’s control system using standardized, proven, field-based communication protocols.

StoneL offers a full array of components to cost-effectively and reliably complete the valve communication network. That includes power supplies, control system interfacing gateways/masters, robust protected drop connector systems, and connectivity accessories.

DOWNLOAD THE STONEL FOOD AND BEVERAGE BROCHURE HERE

Swanson Flo

https://swansonflo.com

800-288-7926

The Increasingly Important Role of Industrial Valve Actuators

Valves are critical components of industries that provide the backbone of the modern world. Because valves are standard in engineering, mechanics, and science, each valve must perform to a specific standard. The valve actuator is as crucial to the valve as the valve is to the industry in which it operates.

Actuators are powered devices that move valves between open and closed states; the actuators can be controlled manually or as part of an automated control loop. The actuator responds to a remote control signal. Valve types can be closed, fully open, or somewhere in between, depending on the valve and actuator combination. Current actuation technology enables remote indication of valve position as well as other diagnostic and operational data. Regardless of its power source, whether electric, hydraulic, pneumatic, or another, all actuators create either linear or rotating motion when controlled by a control source.

Multiple valves in a process system are operated in a coordinated manner thanks to actuators; imagine if engineers in a vast industrial environment had to change every valve through a hand wheel or lever physically! While such a manual system may produce jobs, it is, unfortunately, logistically and economically impractical. Actuators make it possible to automate valve action.

Pneumatic actuators use air pressure as a driving force to adjust the position of a valve. Hydraulic actuators are devices that rely on pressurized fluids. Electric actuators, whether motor-driven or solenoid-driven, use electricity to move the valve trim into position. Changes in valve position provide the needed response to maintain the desired process condition. Signals from controllers constantly monitor the process and evaluate inputs, subsequently adjusting the actuator's motion.

Manual valve operation and regulation are becoming less common as automation gains traction across many industries. Valve actuators serve as the link between control intelligence and physical valve movement. The timeliness and automation advantages of valve actuators also serve as enormous assistance in risk mitigation. Severe tragedies in either environmental conditions or a facility can be pre-empted and rapidly stopped as long as the system is functioning correctly. Manual actuators rely on the hand operation of levers, gears, or wheels in general. Still, valves that are frequently changed (or that exist in remote areas) benefit from an automatic actuator with an external power source for various practical reasons, most notably being located in an impractical area for manual operation or complicated by hazardous conditions.

Actuators serve as industrial keystones to one of the essential control elements of industries worldwide due to their variety and tiered usage. Valves are vital building blocks of industrial processes, just as industries are the backbones of society, with actuators serving as an invaluable device assuring both safe and precise functioning.

Swanson Flo produces tested, certified, and exceptionally reliable actuated valves for fully automated essential valve systems with optimum fit, highest performance, and most extended life. Swanson Flo professionals combine decades of experience and knowledge with a wide range of readily available components that are carefully selected to provide customers with the highest quality and value possible.

Swanson Flo

https://swansonflo.com

800-288-7926

Benefits and Drawbacks of Electric Valve Actuators in Process Control

Electric actuators use electricity to operate a valve. While most of the basic principles utilized in electric actuators have been present since the 1930s, decades of incremental progress have considerably enhanced their capability while lowering their cost. These advancements have reached a tipping point in recent years, making electric actuators the preferred choice for many applications.

There are many advantages to electric valve actuation. Electricity is relatively cheap, simple to control, and usually available at most industrial sites. Electric actuators often have a lower capital cost per equivalent unit of torque/thrust production. They are also more environmentally friendly and safer to use. Electric actuators can provide higher positioning accuracy for control or modulating valve tasks and options for extensive process monitoring, data logging, and information feedback. Electric actuators include all necessary control functions, lowering capital expenditures. By enabling distributed control, the electric actuator's considerable cost in wiring is cut—through efficient and straightforward control logic through integrating control commands and feedback into customer SCADA or DCS systems. (Traditional electromechanical control systems require a distinct wire for each command and feedback signal, resulting in cable bundles with at least seven cores for each actuator.

On the other hand, a standard bus system can use one twisted pair wire in a daisy chain configuration to transport all required input and output signals.) Electric actuators weigh less and have smaller footprints than pneumatic actuators as torque and thrust requirements increase. Finally, electric actuators can generate exceptionally high output thrust and torque values in conjunction with external gears.

There are also some disadvantages to electric valve actuation to note. Except for a few specific combinations, electric actuators cannot ensure a fail-safe stroke. Still, they will "fail in the last position" - the ability of an actuator to move a valve to a specified safe position when power ceases is known as fail-safe stroke. Electric actuators contain more sophisticated and delicate components than other forms of actuators. Electronic technology likewise necessitates regular updating to stay up with component changes and advances. Compared to pneumatic and hydraulic actuators, electric actuators are less cost-effective and have operating speed restrictions beyond a specific size/torque range. Electric actuators require more rigorous certifications and construction features to be regarded safe for usage in hazardous regions with potential exposure to explosive process material.

For more information about electric valve actuation, contact Swanson Flo. Call them at 800-288-7926 or visit their web site at https://swansonflo.com.

Is Your Ashcroft Pressure Gauge Off Zero? Here's Why and How to Fix It

New, open front stainless steel dry or liquid-filled pressure gauges straight out of the box can surprise you with a pointer that is off zero. This may lead you to think that the gauge is defective.

In fact it may just be that the pressure trapped inside the gauge case is higher or lower than the surrounding atmosphere.

Most Ashcroft open front gauges are equipped with a top vent plug. This permits you to open the gauge case allowing the inside and outside pressures to equalize.

Venting or burping gauges with ranges 200 psi and above should not be required.

Before installation, stand the gauge upright to eliminate gravitational effect on the bourdon tube and pointer.

Make sure to prevent fluid leakage if the gauge is liquid filled.

Locate the pop-up plug on top and simply pull up the blue stopper.

To prevent inaccuracy due to zero offset in dry areas, the vent plug can be left open, however this practice should be limited to dry areas because it will lower the ingress rating to IP54 and risk water infiltrating the gauge.

Ashcroft pressure gauges come in various sizes, accuracies, and range from 0 – 10 in. H2O through 0-100,000 psi. Choices include differential pressure gauges, test gauges, sanitary gauges, high-purity gauges, subsea gauges, digital pressure gauges, OEM pressure gauges, and more. Ashcroft pressure gauges are known for high quality and reliability and are available to fit nearly any budget and application requirement.

For more information about Ashcroft products, contact Swanson Flo. Call 800-288-7926 or visit https://swansonflo.com.

O-Ring Style Stem Seal Sanitary Process Control Valves for Cosmetic, Dairy and Food and Beverage Industries

The Steriflow FBCV O-Ring Series meets the rigid specifications for sanitary process control valves for customers who prefer an O-ring style stem seal. This valve series is suitable for various cosmetic, dairy, and food and beverage industries. Conforming to 3A guidelines, the FBCV is ideal for a wide range of flowing media in sanitary systems' utility and process areas.

The FBCV-OR's high rangeability, characterized trim, high capacities, superior temperature and pressure ratings, and a selection of sealing methods make the sanitary control valve ideal for liquid, gas, and steam services. Whether the need is to control pressure, temperature, flow, pH, or another variable, the FBCV is the correct valve for your process.

For more information, contact Swansonflo. Call 800-288-7926 or visit https://swansonflo.com.

The RealStream™ Lift Station Solution

The RealStream™ Lift Station solution is a fully configurable lift station controller and display that enables monitoring and control of lift stations leveraging the Schneider Electric SCADAPack™ E Smart RTU technology. The RealStream™ supports the control of up to four pumps. This easy-to-deploy solution allows standardization of collection network assets and can improve the equipment's visibility and life. The RealStream™ Solution includes a RealStream Lift Station Controller and a Graphic Display Terminal.

Swanson Flo High Purity Valves, Instruments & Process Equipment

Swanson Flo maintains our position as an industry leader in high purity valves and instrumentation by partnering with the world's top manufacturers and satisfying customers with unmatched project success.

Swanson Flo

https://swansonflo.com

800-288-7926

Swanson Flo - An Industry Leader in Process Automation with a Long History of Unmatched Project Success

Founded in 1960, Swanson Flo has long maintained our position as an industry leader in process automation with unmatched project success leveraging industry preferred products and services.

Our team of skilled experts is uniquely equipped to rapidly apply resources and skills for the maximum benefit of our clients. We continue to adapt new technologies and solutions to build solid client partnerships.

Our mission is to provide innovative process control solutions for engineers, managers and maintenance professionals through quality equipment and experienced application engineering. These efforts combined with excellent aftermarket service yield reduced operating costs and improved production.

1960 Thomas B Swanson Co.

Tom B. Swanson saw a need for innovative technical products for industrial applications that was being underserved by the large PVF wholesale houses. Tom started a rep company focusing on new specialty and engineered products.

1974 Swanson Flo-Systems Co.

Tom Swanson and his business partner, Dick Westphal, saw that industrial processes were changing from manual operation to automated systems and solutions to improve quality and gain efficiencies. This forward thinking and vision inspired a new business model of actuation and fabrication to service their customers’ needs, providing automated solutions, while providing a high degree of technical support and customer focus.

1989 Evolution of Swanson Flo Systems

Expands our integration of products by adding control valves and specialty valves to their quality, technical product offering.

1991 Tom Howe acquired Thomas B Swanson equity.

Tom Howe and Dick Westphal continue to serve their customers with a vision to provide full control loop solutions and application engineering experience to the growing market by integrating our products to help customers develop more efficient, productive, and profitable process solutions.

1992 - Acquired Control Dynamics, Co.

The acquisition of Control Dynamics Co. added experienced personnel and additional instrumentation lines including Foxboro and Badger Meter Co. This addition allowed Swanson to provide experienced, technical personnel to assist in the evaluation, specification and application of valves and instrumentation for projects and customer needs.

2001 – Acquired Power Supply and Engineering Co.

Swanson Flo acquires PSE adding Ashcroft instrumentation and additional technical salespeople.

2001 – Acquired Limitorque Actuation Line

Swanson Flo continues their commitment to customers by adding an expanded automation offering with Limitorque. This acquisition created a shift to incorporating services to our product portfolio. Additional square footage was added to handle the services requirement. Expanding in-house repair and field service, and remanufacture electric actuators across the Dakotas, Wyoming, Montana, Minnesota, and Western Wisconsin.

2002 - Acquired Process Sales Inc., Wisconsin

Swanson Flo expands eastward into Wisconsin. Adding Masoneilan Control Valves and Foxboro Instrumentation to the entire state.

2005 - Launched BioFuels Automation Co.

BioFuels Automation becomes a wholly owned subsidiary of Swanson Flo launching the first exclusive renewable fuels focused automation company to serve this rapidly growing industry. Providing a complete solution for automating newly constructed ethanol plants for the future.

2007 - Acquired Failsafe Company

Swanson Flo expands into more quality technical products and experienced people for Wisconsin and Upper Michigan.

2013 - Acquired Valves and Automation Inc.

Swanson Flo adds Limitorque Electric Actuation across Wisconsin, Illinois, Iowa and Indiana, with an expansive shop to repair, assemble and remanufacture electric actuators.

2014 - Acquired Process Sales Inc.

Swanson Flo expands with Masoneilan Control Valves and Foxboro Instrumentation across Upper Illinois and Indiana with full control valve service, repair, and assembly facility.

2016 - Acquired Tech Sales and Marketing - Indiana

Swanson Flo grows in Indiana with additional lines and technical salespeople focused on quality products and customer service.

2021 – Swanson Flo is acquired by MCE to continue to service our customers with an extended offering of highly-engineered, technical solutions by providing leading process control products and services.

The SCG Indu-Tech Level Transmitter Isolation Valve

Universal Mounting

The isolation valve has independent bolting patterns to mount the valve to the tank and the level transmitter. Separate mounting plates ensure a safe working environment when removing a level transmitter from the tank during routine operations.Thin Cross Section

The isolation valve features a thin cross-section, ensuring the level transmitter is as close as possible to the process tank for better measurement accuracy.Lever Handle with Simple Lock Out

The isolation valve includes a 90-degree ¼ turn on/off lever handle. With no exposed apparatus on the handle, operators can open or close on demand, even in situations of long term inactivity.Light Weight and Compact

The Indu-Tech isolation valve weighs under 20lbs (9kg) and is straight forward to install, even in confined spaces that are difficult for larger valve designs. Installation does not require mechanized lifting gear.Bubble Tight Seal

The isolation valve features a close-captured seated ball design, ensuring that the process medium does not build up internally as commonly experienced with open cavity ball valves. Every valve passes strict quality standards for a bubble-tight design before shipment.Swanson Flo

800-288-7926

https://swansonflo.com