This instructional video shows you how to set position limits on the Limitorque L120 electric actuator safely. Explore the video to learn proper equipment terminology, comprehend the wiring diagram concerning the limit switch contact status, and learn how to read the limit switch position.

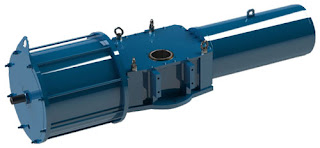

Flowserve Limitorque L120 electric actuators solve many flow control problems in various power, oil and gas, and water industry applications.

L120 actuators are proven performers in demanding applications due to their ruggedness, dependability, and versatility. Thousands of L120 actuators are in use in some of the world's most challenging environments, where anything less than everyday dependability is not acceptable.

Refineries, pipelines, terminals, tank farms, cokers, and offshore platforms rely on the L120's safety, endurance, and operational efficiencies. The L120 is network-compatible, has explosion-proof certification, and is lightning and EMI resistant.

The L120's availability, control versatility, and dependable performance are of particular value in power generation plants. The L120's rugged design and construction quality withstand vibration, high-pressure steam, and extreme temperatures.

The L120's low-maintenance requirements and modulating control capabilities benefit water and waste treatment facilities. L120 actuators comply with AWWA standards and integrate simply into the industry's trend toward modern control networks. The L120 Series' diverse range of options enables easy, cost-effective adherence specification requirements.

For more information about Limitorque actuators, contact Swanson Flo. Call them at 800-288-7926 or visit their web site at https://swansonflo.com.