The Swanson Flo Blog is dedicated to provide educational and new product information on process control instrumentation, control valves, and valve automation. For more information on these products, visit SwansonFlo.com or call 800-288-7926.

Actuators and Valve Automation

Equilibar® Flow Control Valves Provide Advantages in Precision Flow Control

Equilibar® control valves provide precise flow control for gases, liquids, and mixed-phase fluids over a wide range of flow rates. The unique dome loaded multiple orifice design responds quickly to changes in upstream and downstream process disruptions to maintain setpoint,

The Equilibar® control valve works in a completely different way than traditional regulators and valves. Instead of a single valve seat, the Equilibar® valve uses multiple orifices sealed by a flexible diaphragm. The Equilibar® valve is dome-loaded by pressure on top of the diaphragm. The dome loading controls the process fluid flow proportional to that "pilot pressure" on the diaphragm. As flow requirements change, the diaphragm moves a few millimeters to open and close over some or all of the orifices, providing instantaneous and frictionless control. The Equilibar® valve was conceived as a precision back pressure regulator but easily reconfigured to control the flow rate in a flow control PID loop with an electronic pilot controller. Over the years, Equilibar®customers have discovered the significant benefits of the Equilibar®control valve in demanding flow control applications where the supply pressure is mainly stable.

Equilibar® valves can be an excellent solution for closed-loop flow control in complex applications that traditional flow control methods cannot solve. Equilibar® valves improve performance in a variety of demanding applications, including:

- Flow coefficient (Cv) ranges wider than conventional valves (>100:1)

- Extremely low DP and extremely high DP

- Two-phase, phase-change, and supercritical states

- Continuous flow chemistry

- Sanitary applications

The Equilibar® Flow Control Valve's Operation

Equilibar® valves are dome-loaded and pilot operated, which means that gas is supplied to the dome (top) of the valve via a pilot controller to set the process setpoint. In the dome, a direct sealing diaphragm covers a field of orifices and adjusts its position allowing flow through the orifices while maintaining the desired setpoint.

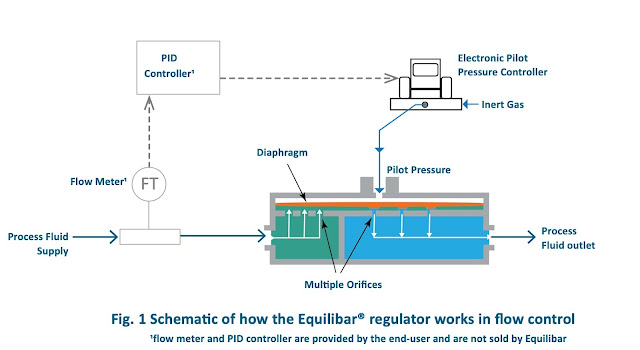

The Equilibar®flow control valve links to an electronic pilot pressure controller and a flow meter in a control loop. (See Fig.1.) To control flow, a proportional-integral-derivative (PID) controller monitors input from a flow transmitter (FT) and adjusts the pilot pressure. The electronic signal from the PID converts into a pressure signal for the pilot controller by an electro-pneumatic transducer (E/P). Increasing the pilot pressure reduces flow, and decreasing the pilot pressure increases flow. The system performs best when the supply pressure is stable.

The Benefits of Using an Equilibar® Back Pressure Regulator for Flow Control

Operates over a Wide Flow Coefficient Range (Cv)

The limited flow range (or max/min ratio of effective Cv) of traditional flow control valves is one of their characteristics. Most control valves used in the research and process industries have a 10:1 to 15:1 ratio. An Equilibar®back pressure regulator is easily capable of operating in a Cv range greater than 100:1.

Multi-Phase Fluid Control

The Equilibar® back pressure regulator's unique design allows it to handle two-phase or mixed-phase flow streams while maintaining high precision. Gas/liquid processes, water/oil flow streams, and supercritical fluids are all examples of this.

Traditional back pressure regulators employ a single annular valve seat, which is frequently very small, so that when slugs of liquid flood the valve throat, the volumetric flow rate drops abruptly as the denser fluid accelerates through the orifice. This brief decrease in volumetric flow disrupts the upstream process pressure's stability.

The Equilibar® technology employs a direct sealing diaphragm over multiple orifices to control pressure drop. The flexible diaphragm can instantly change its proximity to the orifices to adjust to the varying valve coefficient (Cv) requirements of the various phases.

Isolates from Changes in Downstream Pressure

An Equilibar® fluid control valve acts as a pressure buffer in a change in downstream pressure. Equilibar® valves will automatically adjust to maintain the setpoint inlet pressure regardless of process changes at the outlet port. Any change in downstream pressure necessitates a PID control adjustment to maintain stability when using a traditional flow control valve (FCV).

High Resolution

Equilibar® dome-loaded valves have incredibly high resolution, no hysteresis, and no dead band. Minor adjustments to the differential pressure result in high-resolution process control.

Service Conditions That Are Demanding

Because Equilibar® back-pressure regulators have only one moving part, they easily configure for the following severe and demanding service conditions:

- Excessive temperatures

- Extremely corrosive acids

- Sanitary processes

- Ultrapure specifications

Continuous Flow Reactions

In continuous flow chemistry, controlling pressure is critical for phase control, residence time, reaction speed, and equilibrium management. For example, the reaction temperature is an essential factor in reaction efficiency; however, at high enough temperatures, a reagent can reach boiling point, which harms the reaction. Controlling reaction pressure by connecting a back pressure regulator to the reactor's outlet can help prevent reagent boiling.

For more information about Equilibar®, contact Swanson Flo. Call 800-288-7926 or visit https://swansonflo.com.

Attend the 2019 BioFuels Automation University Ethanol Maintenance Classes

BioFuels Automation University provides Best Practice Certification courses designed to enable participants to learn directly from some of the industry’s top technical professionals and gain valuable hands-on training to best utilize the technology driving your facilities.

Ethanol Maintenance 101

A strong combination of concepts and best practice Hands-on Training – this course really delivers for insight and troubleshooting skills for instrumentation and valve technologies. BioFuels Automation University experts stand ready to help define your needs and craft a customized program.

- Jun 20 - 21, 8:00 AM

- Oct 24 - 25, 8:00 AM

Day Two: Valves - Automated On/Off Valves, Valve Monitors, Control Valves, Positioners, Communication Protocols, Shop Tools - Hands On

Fee: $1,350 per participant. Fee includes lodging and meals. Payment information required to complete registration.

Location: BioFuels Automation University Training Center, 151 Cheshire Lane, North Plymouth, Minnesota

Ethanol Maintenance 201

This class will take you through an analysis of the complete control loop, providing you with a deeper understanding of the relationship between the three segments of a control loop. Sensing Element, PID Controller, Final Control Element, C (control) DCS, I and V.

- July 25 - 26, 8:00 AM

- Dec 05 - 06, 8:00 AM

Topics covered: Loop Configurations, Controller PID Tuning: Theory and Practical Application Instruments, Advanced Valves

Fee: $2,250 per participant. Fee includes lodging and meals. Payment information required to complete registration.

Location: BioFuels Automation University Training Center, 151 Cheshire Lane, North Plymouth, Minnesota.