|

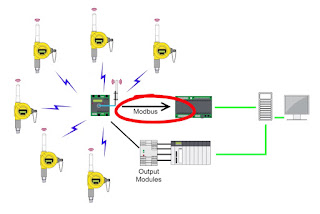

| Wireless Process Control Instrumentation Diagram |

Wireless process control technology is a serious contender in the ongoing effort to improve plant efficiency, mitigate risk, and increase productivity. Today's wireless transmitters are available for monitoring virtually any process control variable including flow, pressure, level, temperature, pH, Dissolved Oxygen, etc. Very notably, in the harshest environments, these devices reliably transmit critical control data back to central control areas around the clock and without the need for human presence.

The argument for wireless instrumentation is very compelling when you consider installation convenience and cost savings. Some cost savings estimates run as high as 70% by eliminating wires and cables, as opposed to the cost when using cables for the same application. And most remarkably, wireless instruments provide additional safety and compliance benefits by keeping maintenance personnel out of dangerous or hazardous areas.

All manufacturing industries are faced with the realities of cost cutting as plant managers endeavor toward continuous process improvement. The need for better solutions is always present, and wireless process instruments certainly appear to fit the bill. But before widespread adaptation of wireless occurs, concerns about reliability, user comfort, and integration must be overcome. However, as plant managers see the downward pressure on deployment and maintenance costs, and as they see improved employee safety and smoother environmental compliance, adoption of wireless instrumentation will accelerate and eventually become ubiquitous in process control.