The Swanson Flo Blog is dedicated to provide educational and new product information on process control instrumentation, control valves, and valve automation. For more information on these products, visit SwansonFlo.com or call 800-288-7926.

Actuators and Valve Automation

Demonstration of Ultra Low Flow Control Loop Combining the Equilibar Precision Valve and the Bronkhorst Mini CORI-FLOW™ Meter

Fractional Flow Control Valves from Swanson Flo

For Critical Fractional Flow Control of Liquid, Gas, or Steam

LowFlow control valves have applications in OEM, laboratory, and pilot plant applications. Installations such as these frequently require valve trim changes to meet varying flow requirements for a given application. Monel, Hastelloy, Alloy 20, Titanium, Kynar, and Inconel are just a few of the materials LowFlow offers to address your material compatibility challenges.

Gas Flow Measurement & Control - Aeration Applications

Many processes include gas flow measurement and control. Gas flow meters are standard in laboratories, machinery, industry, hazardous areas, and various markets, including the analytical market, the chemical industry, renewable energy, the semiconductor industry, the food and beverage industry, and surface treatment.

Applications for Aeration

Aeration is when air, oxygen, carbon dioxide, or other gases circulate, mix, or dissolve in a liquid or substance.

Aeration applications are typical in food and beverage markets, wastewater treatment, fish tanks, and fish farms. Controlling oxygen levels in beer brewing and winemaking, for example, allows fermentation. Milk, sparkling water, and other carbonated beverages, such as cola require a throughflow of gases to remove odors or add CO2. Industrial gas flow control, similar to air pumps in a fish aquarium, is used to aerate ponds to grow fish or algae.

Gas Flow Aeration Markets:

- Winemaking and beer brewing

- Production of carbonated beverages

- Fermenters and bioreactors

- Treatment of wastewater

- Farms for fish and algae

Why Bronkhorst?

- Robustness

- High repeatability

- Easy to check actual gas flow

- Gas consumption monitoring

- Ingress protection class IP65 rugged and waterproof housing

Bronkhorst provides mass flow meters and controllers with capacities of up to 5000 ln/min Air equivalent. In aeration applications, up to 50% of MASS-STREAM flow measurement and control instruments include a multi-functional display that provides various additional options.

Bronkhorst is a company that specializes in gas flow measurement and control instruments.

For more information about Bronkhorst products in North Dakota, South Dakota and Minnesota contact Swanson Flo. Call 800-288-7926 or visit https://swansonflo.com.

New Product Alert: The Jordan Valve Mark 75A

Jordan Valve Introduces the Mark 75A Wafer Style Control Valve

Jordan Valve designed the Mark 75A as the next generation of control valves with its modular, stackable actuator. The Mark 75A incorporates a modular, stackable actuator to reduce weight and footprint dimensions further while providing additional torque and all of the benefits of the time-tested Sliding Gate seat design in a lightweight, compact body. The Mark 75A, which is available in 1" through 6" (DN25 - DN150") sizes, is a high-value solution used in a variety of applications.

DOWNLOAD THE MARK 75A DATA SHEET HERE

Mark 75A Advantage: An Actuator with Modularity and Stackability

The new actuator design has an effective diaphragm area of 25 square inches per module and can be stacked to increase the total effective area to 50 or 75 square inches. The use of aluminum in the construction ensures a lightweight automated package.

Mark 75A Advantage: Less Weight

The Mark 75A has a significant weight advantage over other valve designs. A 4" Mark 75A with a 75M actuator weighs 27 lbs. Because of the lightweight and reduced envelope dimensions, transportation, installation, and support costs are lower.

For more information about the Mark 75A in Wisconsin, Indiana, Minnesota, South Dakota and North Dakota, contact Swanson Flo. Call them at 800-288-7926 or visit https://swansonflo.com.

Equilibar® Flow Control Valves Provide Advantages in Precision Flow Control

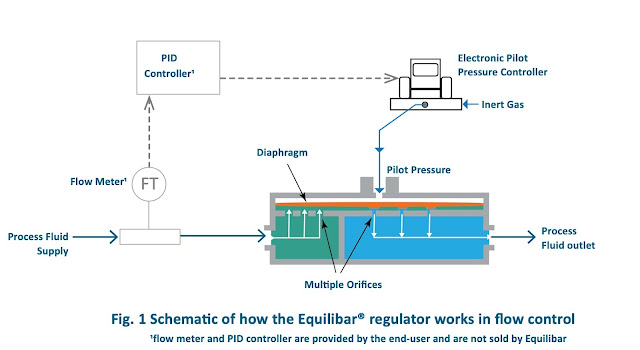

Equilibar® control valves provide precise flow control for gases, liquids, and mixed-phase fluids over a wide range of flow rates. The unique dome loaded multiple orifice design responds quickly to changes in upstream and downstream process disruptions to maintain setpoint,

The Equilibar® control valve works in a completely different way than traditional regulators and valves. Instead of a single valve seat, the Equilibar® valve uses multiple orifices sealed by a flexible diaphragm. The Equilibar® valve is dome-loaded by pressure on top of the diaphragm. The dome loading controls the process fluid flow proportional to that "pilot pressure" on the diaphragm. As flow requirements change, the diaphragm moves a few millimeters to open and close over some or all of the orifices, providing instantaneous and frictionless control. The Equilibar® valve was conceived as a precision back pressure regulator but easily reconfigured to control the flow rate in a flow control PID loop with an electronic pilot controller. Over the years, Equilibar®customers have discovered the significant benefits of the Equilibar®control valve in demanding flow control applications where the supply pressure is mainly stable.

Equilibar® valves can be an excellent solution for closed-loop flow control in complex applications that traditional flow control methods cannot solve. Equilibar® valves improve performance in a variety of demanding applications, including:

- Flow coefficient (Cv) ranges wider than conventional valves (>100:1)

- Extremely low DP and extremely high DP

- Two-phase, phase-change, and supercritical states

- Continuous flow chemistry

- Sanitary applications

The Equilibar® Flow Control Valve's Operation

Equilibar® valves are dome-loaded and pilot operated, which means that gas is supplied to the dome (top) of the valve via a pilot controller to set the process setpoint. In the dome, a direct sealing diaphragm covers a field of orifices and adjusts its position allowing flow through the orifices while maintaining the desired setpoint.

The Equilibar®flow control valve links to an electronic pilot pressure controller and a flow meter in a control loop. (See Fig.1.) To control flow, a proportional-integral-derivative (PID) controller monitors input from a flow transmitter (FT) and adjusts the pilot pressure. The electronic signal from the PID converts into a pressure signal for the pilot controller by an electro-pneumatic transducer (E/P). Increasing the pilot pressure reduces flow, and decreasing the pilot pressure increases flow. The system performs best when the supply pressure is stable.

The Benefits of Using an Equilibar® Back Pressure Regulator for Flow Control

Operates over a Wide Flow Coefficient Range (Cv)

The limited flow range (or max/min ratio of effective Cv) of traditional flow control valves is one of their characteristics. Most control valves used in the research and process industries have a 10:1 to 15:1 ratio. An Equilibar®back pressure regulator is easily capable of operating in a Cv range greater than 100:1.

Multi-Phase Fluid Control

The Equilibar® back pressure regulator's unique design allows it to handle two-phase or mixed-phase flow streams while maintaining high precision. Gas/liquid processes, water/oil flow streams, and supercritical fluids are all examples of this.

Traditional back pressure regulators employ a single annular valve seat, which is frequently very small, so that when slugs of liquid flood the valve throat, the volumetric flow rate drops abruptly as the denser fluid accelerates through the orifice. This brief decrease in volumetric flow disrupts the upstream process pressure's stability.

The Equilibar® technology employs a direct sealing diaphragm over multiple orifices to control pressure drop. The flexible diaphragm can instantly change its proximity to the orifices to adjust to the varying valve coefficient (Cv) requirements of the various phases.

Isolates from Changes in Downstream Pressure

An Equilibar® fluid control valve acts as a pressure buffer in a change in downstream pressure. Equilibar® valves will automatically adjust to maintain the setpoint inlet pressure regardless of process changes at the outlet port. Any change in downstream pressure necessitates a PID control adjustment to maintain stability when using a traditional flow control valve (FCV).

High Resolution

Equilibar® dome-loaded valves have incredibly high resolution, no hysteresis, and no dead band. Minor adjustments to the differential pressure result in high-resolution process control.

Service Conditions That Are Demanding

Because Equilibar® back-pressure regulators have only one moving part, they easily configure for the following severe and demanding service conditions:

- Excessive temperatures

- Extremely corrosive acids

- Sanitary processes

- Ultrapure specifications

Continuous Flow Reactions

In continuous flow chemistry, controlling pressure is critical for phase control, residence time, reaction speed, and equilibrium management. For example, the reaction temperature is an essential factor in reaction efficiency; however, at high enough temperatures, a reagent can reach boiling point, which harms the reaction. Controlling reaction pressure by connecting a back pressure regulator to the reactor's outlet can help prevent reagent boiling.

For more information about Equilibar®, contact Swanson Flo. Call 800-288-7926 or visit https://swansonflo.com.