|

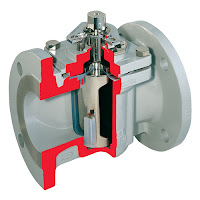

| Lubricated plug valve. (Flowserve Durco) |

Fluid process control operations commonly employ pumps, piping, tanks and valves as the means of transporting, containing and controlling the fluid movement through a system.

Valves, of which there are many types, provide control over the flow rate, direction and routing of fluids in a processing operation. Flow can be started, stopped or modulated between zero and full rate using a properly sized and configured valve. Some valves enable media flow to be diverted to a selection of outlets, in lieu of a single inlet and outlet pair. Specialized valves regulate inlet or outlet pressure, or prevent fluid flow from going in an undesirable direction. All of these capabilities are packaged into differing valve product offerings that present a very large selection array to a process designer or engineer.

|

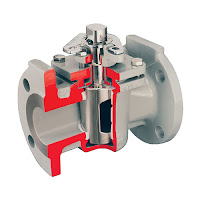

| Non-lubricated plug valve. (Flowserve Durco) |

Plug valves, like ball and butterfly valves, span from fully open to fully closed positions with a shaft rotation of 90 degrees. The “plug” in a plug valve is installed in the flow path within the valve body and rotated by means of a stem or shaft extending to the exterior of the body. Plugs are tapered toward the bottom and are fitted to a seating surface in the valve body cavity that prevents fluid from bypassing the plug. An opening through the plug, the port, can be shaped to provide particular flow characteristics. There are two main types of basic plug, lubricated and non-lubricated. Lubricated plug valves have a cavity into which a sealant is injected. The sealant provides a renewable seal between the plug and the body, prevents internal leakage, and protects the seating surfaces against corrosion. Non-lubricated plug valves utilize an elastomeric body liner or a sleeve in the body cavity that is pressed in to the body of the valve by the plug's wedge-like shape, with the result of reducing the friction between the plug and the body.

Plug valve considerations:

- 90 degree rotation from open to closed provides fast operation.

- With proper configuration, can be well suited for frequent operation.

- Availability of corrosion resistant liner may provide comparative cost savings because valve body can be constructed of less expensive material.

- Design is simple and employs a low parts count.

- Valve can be serviced in place.

- Generally, low resistance to flow when fully open.

- Reliable leak-tight service due to tapered plug wedging action, replaceable sleeve, and injection of lubricant in some variants.

- Potential issues of concern for plug valve application include a short list of items.

- Higher friction in the plug closure mechanism may require comparatively higher operating torque than other valve types.

- Without a specially designed plug, generally not well suited for throttling applications.

- Rapid shutoff delivered by plug design may not be suitable for some applications where hammering may occur.